sistemas de control de polvos

BLOG

Dust, fume and mist control systems

What is a dust collector, fume collector, or mist collector?

They are systems that allow companies to efficiently control suspended particles in the environment within a factory, workshop, laboratory, foundry, work plants or outdoors such as quarries, cement plants, mining, among others, these particles are released during The various production processes

are mostly fine particles down to 0.5 microns, so it is very important to keep them under control, thus avoiding possible damage to the health of employees, contaminating the work area and the environment.

These equipments fulfill the important function of constantly filtering the air, capturing suspended particles through a system of ductwork, extractor hoods and a filtration system, which allows the air to be cleaned and returned back into the facilities or expelled to the environment. completely free of contaminants.

What type of control system do I need?

To know which is the ideal system for the needs of your company, it is very important to have the advice of specialist personnel in Dust, Smoke and Mist Control Systems since each case requires a particular analysis, in which it is necessary to evaluate and determine several factors, in addition to listening to the operators of the current systems to know the needs in depth and thus be able to choose the correct system that adapts to the needs, solves the problem, is easy to operate, that has the necessary performance and its maintenance is simple.

At Grupo Oasis we have our own specialized engineering department and a team of consultants prepared to help you in every step of your project.

sistemas de control de polvos /

sistemas de control de polvos

sistemas de control de polvos / Grupo OASIS fabricamos colectores de polvos humos y neblinas. La versatilidad de nuestros Colectores de Polvos, Humos y Neblinas marca DYNAFLO®. brand, the attention to detail during the manufacturing and installation process allowed us to work in Mexico and United States.Nuestros clientes de las industrias agroalimentaria, cementera, química, cerámica, automotriz, acerera, entre otras más nos respaldan.Nuestra amplia gama de productos como colectores de polvos, colectores de humos, colectores de neblinas, ciclones, colectores de humos portátiles, ventiladores industriales, válvulas rotatorias, filtros y refacciones, además de proyectos llave en mano, capacitación y mantenimiento de equipos nos permiten brindar servicios integrales.

Where do I start to choose the collector system I need?

Analyzing the characteristics of the product to be collected is very important, since from there you can establish the needs, such as, if it is: corrosive, hygroscopic, flammable, abrasive, dense, micro particles, operating time, etc.

This allows defining the type of system, the manufacturing materials, the components, their capacity and performance, size, location, etc., as well as identifying where in the process a dust, fume or mist control system is required. , where you need to place the capture hoods, the force of the air flow, the ductwork and how to adapt the various components of the system to the product to be collected.

For exampleif the product is moistened in any part of the process, you will not need dust control at that point, but if it is dry and can get wet, a dust control will not be necessary either, if it is corrosive, then the components of the system They must be manufactured with special materials and finishes.

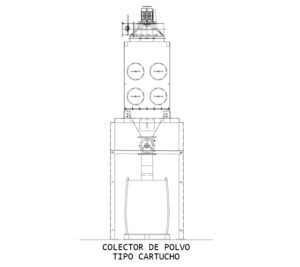

Cartridge and Cyclone Dust Collector System

Tips DYNA FLO®: Con el uso de tecnología, se puede monitorear la operación diaria, a cada momento y desde cualquier parte los sistemas de colección de polvos, humos y neblinas DYNA FLO®, esto permite obtener información real y oportuna para prevenir o corregir anormalidades durante su operación, programar mantenimientos y cambios de filtros.

Other articles of interest

Rule 484 – Combustible Metals

Good practices in the management of Combustible Metals within companies are based on the NFPA (National Fire Protection Association) standard 484, this standard establishes the appropriate parameters for the prevention and management of these residues, such as: potassium , magnesium, zirconium, titanium, sodium and lithium.

What type of industrial ventilation system do I need for my company?

Ventilation systems are used to ventilate closed spaces in the industrial or commercial sector, their function is to regulate the temperature, renew the air, extract dust, smoke, mist or gases, prevent…

Hoppers and Rotary Valves

A dust collector is made up of various parts that fulfill a specific function, all its components are made of very resistant materials, they must tolerate abrasions, high pressures and corrosion, such as deposit hoppers and rotary valves.