tolvas y válvulas rotatorias, tolvas de depósito

tolvas y válvulas rotatorias, tolvas de depósito

Hoppers and Rotary Valves

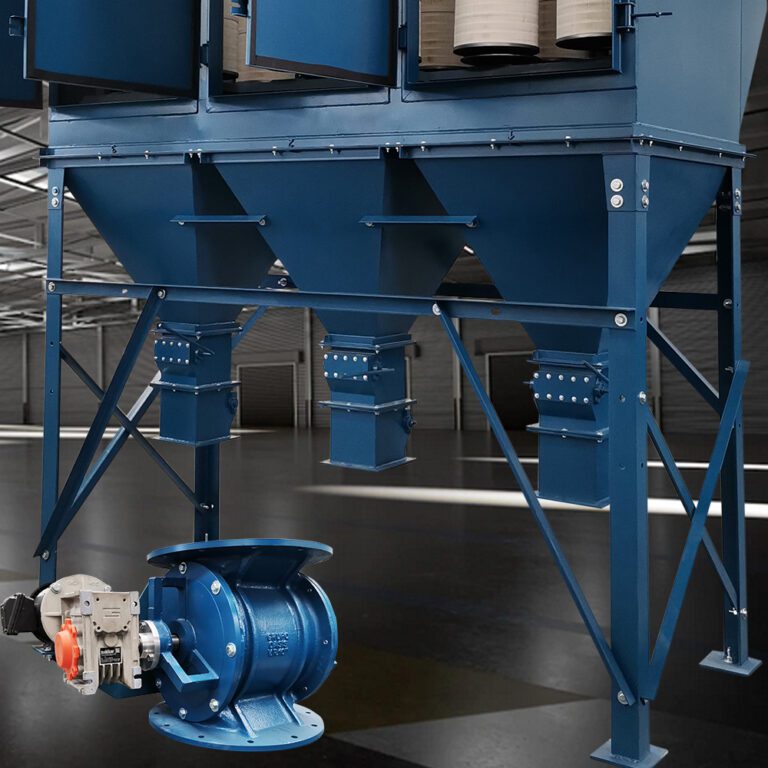

A dust collector is made up of various parts that fulfill a specific function, all its components are made of very resistant materials, they must tolerate abrasions, high pressures and corrosion, such as deposit hoppers and rotary valves.

What is a hopper?

A hopper, is a deposit that allows to temporarily store the powders of the materials with which they work, these are captured through the suction hoods, they travel through the ducts, these particles accumulate when they reach the filters and thanks to a system of automatic or mechanical cleaning, they come off the filters and fall into this, its characteristic shape, it is conical or trapezoidal. In a dust collector, it is located in the lower part of it, allowing the waste to accumulate in it, they are made of high-strength steel, this allows it to fulfill its function, the material to be collected is the determining factor for its Design and manufacturing.

What is the function of the hoppers?

The main function of the hopper in a dust collector is to serve as a transition medium, that is, the material that will accumulate in it can be evicted through its lower opening, this must have one with a gate type guillotine or a rotary valve that allows the dosing of the materials.

Discarded materials can be deposited in super bags, tanks or directly in trucks.

What is a rotary valve?

A rotary valve or rotary valve, is an element that is part of a dust collector, its main function is to dose powdered materials and it is regularly located under the hopper.

These can be manufactured in:

- Acero al carbón

- Stainless steel

Its design and manufacture must resist wear, corrosion and avoid adhesions.

Both elements, the hopper and the rotary valve, are an important part of a dust collector, when developing a dust control project, specialist engineers must accurately survey the needs, since this will determine the characteristics that The industrial collector must have, its capacity and elements that it must have to perform its function efficiently.

Hoppers and rotary valves on dust collectors

Commonly, cartridge-type collectors or bag-type collectors use hoppers as temporary storage, since the materials deposited in them must be constantly removed, hoppers cannot keep materials for a long time, since this directly influences the collector performance, that is, the more materials are accumulated in the hopper, this generates a resistance inside the collector, and can cause pressure drops or cause damage to the filters.

Bulk materials can be easily disposed through the hopper with the help of a rotary valve, which gradually doses the waste, thereby preventing it from generating dust clouds again.

Some of the materials that are discarded through the hoppers and rotary valves are; coal dust, cement, iron, ceramics, marble, granite, steel, wood, cocoa, corn, to name a few.

The humidity of the materials must also be taken into consideration. This analysis is a fundamental part and therefore must be carried out by highly qualified personnel in the design of dust collection equipment. At Grupo Oasis, we have more than 35 years of experience. experience in the design and manufacture of Dust Collectors.

Safety in the hoppers and rotary valves

Safety is another important factor to review in a hopper, excessive dust accumulation can result in these completely blocking or covering ducts for other functions, explosions due to dust accumulation is also something that must be taken into account. consider.

Our rotary valves can be 8, 10, 12, 14 and 16 inches, we are direct manufacturers.

Another application of rotary valves is in conveyor belts, silos, among others.

DYNA FLO® Tips:

- Before making any modification or relocation of your dust collector, consult with us.

- If you require a reliable analysis to implement the best solution for dust control, contact us, we are ready to help you.

- Analyze the potential risks and possible risk scenarios in your company.

Optimize your dust collection system with our rotary hoppers and valves!

At Grupo OASIS, we specialize in providing complete solutions for efficient dust control, and our hoppers and rotary valves are essential components to optimize your dust collection system. Our team of experts is ready to help you select the right hoppers and rotary valves for your dust collection system:

dust collector maintenance, collector maintenance, collectors

polvos combustibles, colectores industriales, colectores para industrias, filtrado de neblinas, filtrado de humos, neblinas, niebla, empresas de ventilación industrial

Other articles of interest

Benefits of Preventive Maintenance

Have you ever wondered how much money preventive maintenance on your equipment or machinery saves you? It is undoubtedly one of the most frequent questions we ask ourselves while making budgets for this area in companies.

Airborne particles What are they?

Pollutants in the atmosphere are more common than we all think, they directly impact the environment and health. Suspended particles as it is commonly known...

Particle Filtration

In most production processes, micro particles are generated that remain suspended in the air, these are breathed in directly by workers and can cause various respiratory diseases.