Tipos de sistemas de ventilación industrial

Tipos de sistemas de ventilación industrial

Tipos de sistemas de ventilación industrial

BLOG

What type of industrial ventilation system do I need for my company?

Ventilation systems are used to ventilate closed spaces in the industrial or commercial sector, their function is to regulate the temperature, renew the air, extract dust, fumes, mists or gases, avoid humidity and that by its nature does not have a Natural ventilation….

Modern industry and ventilation systems

In recent years, the industry in Mexico is reinventing its way of working, including and prioritizing important issues such as safety and hygiene, in this area, there is the issue of health care for employees who work in closed areas with little or no natural ventilation, for which they are implementing measures that allow them to comply with the provisions of Mexican regulations such as NOM-019-STPS-2004 among other.

Investing in systems with technology that is more efficient, that is friendly to the environment, that allows less energy consumption, that its maintenance is simple and at low cost; and also that it allows companies to reduce the risk of virus or bacteria proliferation by having special filters for this type of case.

Role of ventilation systems

The main function of ventilation systems is to provide a solution that allows industrial-type companies to move contaminated air to renew it with clean air, control gases, vapors, dusts or fumes that are generated during their various production processes, accumulating inside the plants or factories and could cause damage to health to mention a few examples, thus avoiding setbacks in production or work absences due to respiratory diseases.

In the commercial area, such as squares, cinemas, party halls, shopping centers, industrial warehouses to mention a few, they are implemented to extract stale or polluted air and inject clean air, in addition, they manage to create an atmosphere of comfort that allows workers or clients feel comfortable in them.

Types of ventilation system

In order to implement a ventilation system in a company, be it industrial or commercial, you must first know the types that exist and their applications, such as:

Comfort ventilation

This focuses on air conditioning, with it it is intended to provide pleasant conditions in the work environment, that is, that people can be in a specific or general area with a comfortable temperature.

Natural ventilation

This is the most common in homes, it consists of having an air flow through any opening such as windows or vents, thus allowing the displacement of stale air in a natural way and in turn, allowing the entry of clean and fresh air.

Evacuation Ventilation

This is commonly applied in cases that require moving large volumes of polluted air, it is generally located with local applications as close as possible to the initial point where the pollutants are generated.

Colector de polvos industrial

Forced ventilation

Commonly applied in large companies, this type of ventilation allows through diffusers to inject fresh and clean air into the facilities, on the other hand, the use of industrial fans can also be implemented to be placed at strategic points.

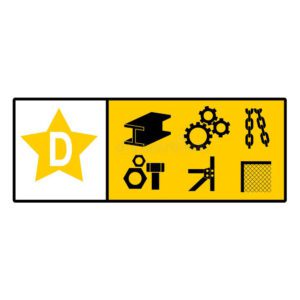

ventilación industrial colectores

Analysis and design of a ventilation system

Before investing in a ventilation system, contact a specialist who should help you identify the necessary characteristics, in addition to providing you with the necessary information on what type of system the company needs.

The analysis of the needs by the specialists will allow the identification of the necessary points where the ductwork system needs to be placed, the extraction force and the air injection force, everything that is required for the correct operation of the system. .

Maintenance

The correct operation of the equipment depends in most of the situations of the preventive maintenance carried out, the preventive services allow to correct and anticipate possible damages, this guarantees that its constant and efficient operation, in addition to prolonging the useful life of the system.

It is very important to have within the annual budget an item for the maintenance and monitoring of this type of equipment and schedule it when the manufacturer indicates it.

ventilación industrial colectores

Tips DYNA FLO®

- Always consult with specialists before investing in any type of ventilation system.

- Carry out the maintenance of your ventilation system, always with personnel specialized in the matter.

- If you change damaged parts, make sure they are original, this ensures that the system works correctly.

Other articles of interest

Hoppers and Rotary Valves

A dust collector is made up of various parts that fulfill a specific function, all its components are made of very resistant materials, they must tolerate abrasions, high pressures and corrosion, such as deposit hoppers and rotary valves.

Rule 484 – Combustible Metals

Good practices in the management of Combustible Metals within companies are based on the NFPA (National Fire Protection Association) standard 484, this standard establishes the appropriate parameters for the prevention and management of these residues, such as: potassium , magnesium, zirconium, titanium, sodium and lithium.

Fire risk

One of the main concerns of insurance companies and business owners is the latent threat of fires within the facilities due to dust accumulation, which are a possibility.