Renovar viejo colector de polvos

BLOG

High concentration of dust in closed spaces

The high concentration of dusts, fumes or mists in closed spaces, represent a great risk to health for employees, the particles that remain suspended in the air are breathed by them and in some cases, these can become very toxic due to its origin.

Normally the particles or vapors that come from heavy metals and chemicals to name a few, generate serious complications in the health of employees, but they can also impact people who work or live near the factory. Respiratory infections are proven to be complicated by the high concentration of harmful particles suspended in the air.

Equipment failures due to accumulation of dust

Another factor to consider in order to have dust, smoke or mist collection systems is the damage that machinery or equipment can suffer, since there are residues that form layers of dust and these, when accumulated, cause corrosion and therefore cause damage. , they also decrease the life time of these.

Corrosion of metals, damage to parts such as vials, rotors, belts or fans to mention a few, are the most common, this can imply delays in daily operation, since damaged equipment must stop to be repaired, they can also occur accidents due to equipment damage; all this directly impacts the economic and time issues.

control de polvos en espacios cerrados

Environmental impact

In some cases, companies expel the air that is inside the factories to the atmosphere without filtering it, since they do not have a control system, this allows the heavy metal particles to be spread in the environment, which It contributes to increasing pollution rates and drastically reducing air quality.

In Mexico, the standards of STPS NOM-019-STPS-2004 and SEMARNAT NOM-085-SEMARNAT-2011, among others, establish that companies and factories must have ventilation and dust control systems in case of carrying out activities that thus deserve it, with this it is sought that companies have equipment that helps filter the air inside these, either to make it recirculate in their facilities or be released into the atmosphere, thus generating the least possible damage to the health of the employees and the environment.

Cartridge collector for dust control.

Control of Dusts, Smoke and Mists

Industrial collector systems are specialized equipment that allows controlling the dusts, fumes or mists that are generated within the facilities during the production processes. These equipments fulfill an important function, to capture the polluted air within the facilities through a ductwork network and thanks to a special filter system, it captures and eliminates harmful particles, thereby improving air quality.

Thanks to this equipment, the air can be cleaned to be injected back into the facilities or released into the atmosphere, but with the certainty that it is clean air free of pollutants.

Important note:

If your company has problems controlling dust, fumes or mists, you can contact us and together find the best solution.

We have an engineering department specialized in the design and manufacture of equipment.

control de polvos en espacios cerrados

Renovar viejo colector de polvos

DYNA FLO® Tips:

- Before designing a dust control system, consult with us.

- Consider the maintenance of your collectors in your budgets.

- Take into account the opinion of the operators for the design of the collectors.

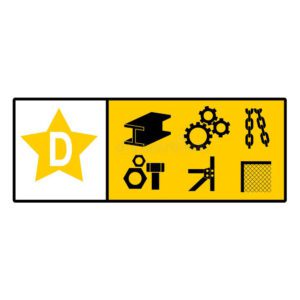

Collector Types

control de polvos en espacios cerrados

Other articles of interest

Rule 484 – Combustible Metals

Good practices in the management of Combustible Metals within companies are based on the NFPA (National Fire Protection Association) standard 484, this standard establishes the appropriate parameters for the prevention and management of these residues, such as: potassium , magnesium, zirconium, titanium, sodium and lithium.

Dust, Smoke and Mist Control Systems

What is a dust collector, smoke collector or mist collector? They are systems that allow companies to efficiently control suspended particles in the environment within a factory, workshop, laboratory...

Hoppers: Function and Application

The hoppers are part of the structure of the dust collectors, they fulfill a very important function, which is to channel the materials, whether they are granulated, pulverized, among others, towards the container where the collected material will be stored. These are mounted on a rigid chassis that serves as a support, their shape is regularly conical and with sloping walls.