tolvas colector de polvos, grupo oasis colectores industriales, materiales industriales, herramientas industriales, colector de polvo

tolvas colector de polvos, grupo oasis colectores industriales, materiales industriales, herramientas industriales, colector de polvo

Hoppers: Function and Application

The hoppers They are part of the structure of the dust collectors, they fulfill a very important function, which is to channel the materials, whether they are granulated, pulverized, among others, towards the container where the collected material will be stored. These are chasis rigid that serves as a support, its shape is regularly conical and with inclined walls.

The characteristics for the manufacture of the hopper will depend on the type of application, such as, material from which it must be manufactured, the degree of inclination of its walls, volume of material that will pass through it, diameter of the sluice through which the materials will be disposed of. , to name a few.

It is very important to consider the degree of inclination of the walls, since it depends on this that the material does not accumulate.

Recovery of Materials

In many companies, the materials that are recovered thanks to the dust collectors can be reused, in this part the hoppers intervene, since, by functioning as a transition, the materials that are to be reused can be stored in the container by the bottom and / or connected with a rotary valve to the same process. Although also, the materials can be recovered to be recycled correctly and give them the appropriate treatment to avoid polluting the environment.

Applications

Hoppers are used in dust collectors, but they also have applications in the agricultural, food, medical, plastic, and bulk industries, among many others.

Discharge dimensions

An important point to take into account is the diameter of the discharge mouth, since the materials will pass through there to be deposited in a container, boat or super sack. Normally it is a square flange, its dimensions vary because, the more material accumulates in the outlet, the larger the diameter must be.

Some of the most common measurements are 10 ”x 10”, 12 ”x 12”, 14 ”x 14”, this last measurement is applied when the materials are fibrous, such as fiberglass, since static charges are generated.

The height of the discharge to the floor must always be considered within the engineering, this due to the type of container that is placed, normally the free distance from the mouth of the hopper to the floor is 48 ”free, since the most Common used to store waste are 200-liter drums.

DYNA FLO® Tips:

- Before investing in an industrial ventilation system, consult with us, call us and we will gladly assist you.

Collector Types

tolvas colector de polvos, grupo oasis colectores industriales, materiales industriales, herramientas industriales, colector de polvo

tolvas colector de polvos, grupo oasis colectores industriales, materiales industriales, herramientas industriales, colector de polvo

Other articles of interest

What is an Electrostatic filter?

This type of filter allows the capture of micro particles such as cigarette smoke, soot, aerosols or bacteria that float in the environment, designed to help improve environmental conditions in hospitals, shopping centers, offices, movie theaters, to name a few. allow you to create a safe and comfort zone.

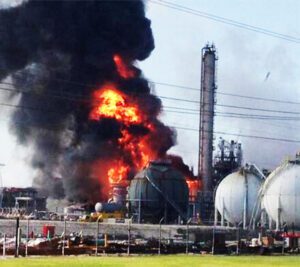

Explosive Atmosphere and Ventilation Systems

During the various production processes, there are some materials that can create an explosive atmosphere and therefore high risk if proper handling and control of them is not carried out, since these…

5 key points to invest in a collector

During 2022, the industrial sector around the world is facing the challenge of continuing to protect the health of employees, improve the conditions of the work area, avoid emitting pollutants into the atmosphere at all costs and make the most of the company's budget. Without a doubt, these are some of the challenges that require the use of equipment and technology, in addition to an effective analysis that allows them to be faced and solved.