Colector de Polvos Industrial

BLOG

What is the function of an Industrial Dust Collector

The industry around the world generates large volumes of pollutants daily, this due to the various production processes, which directly affects the quality of the air inside the factories and the environment outside, consequently the rates increase pollution ...

Role of a Dust Collector in Industry

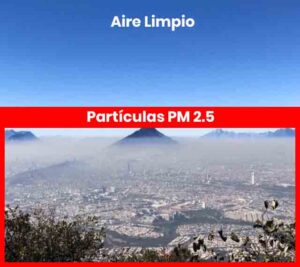

The PM 2.5 or less particles that are suspended in the work environment or outside, are the main challenge for industrial or commercial companies, whether they are dusts, fumes, mists or gases, these must be controlled during production by specialized systems to avoid greater impact on the environment in general, that is why it is important to have these systems and comply with the various regulations for environmental protection and labor standards.

If you do not know what type of systems need to be implemented in your company, consult specialized advisers.

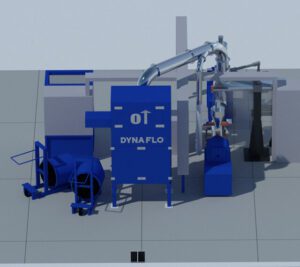

Colector de Polvos Industrial

Some of its applications :

When crushing or cutting materials such as stone, marble, granite, ceramics, among others, they give off dust that accumulates in the work environment and therefore can be breathed in by employees, also if there is no system in place. to collect these emissions they escape into the atmosphere and generate pollution.

In the processes of extrusion of metals, cuts with saws in which it is required to apply a coolant (oil-based or water-based), or some other additive, these generate an oily mist which must be captured to avoid being breathed.

Another issue that concerns companies is the smoke or residues that are generated during welding processes such as FCAW (Flux Cored Arc Welding), GMAW (Gas Metal Arc Welding), SMAW (Shielded metal arc welding), SAW (Submerged arc welding ), GTAW ( gas tungsten arc welding), metal foundries, in which extraction systems can be used for their control or recovery of materials.

In addition, there are also metal cutting processes such as oxyfuel and plasma.

If you want to know more applications of dust, fume or mist collection systems, visit our article Types of Industrial Collectors

Clean Air

These systems are implemented in companies, whether industrial or commercial, to improve air quality by eliminating impurities, allowing employees to work in a comfortable and safe area.

Recovery of Materials

The recovery of materials is also very important, since they can be reused, this is achieved through a process of capture, filtration and at the end they are deposited in containers for reuse.

Improve the Work Environment

By implementing these systems, the air quality within the work area is improved and therefore the Health of the employees is protected.

Colector de Polvos Industrial

Colector de Polvos industrial

Colector de Polvos Industrial

Parts of a Dust Collector

The system of a dust collector is composed of various parts that fulfill a specific function, such as:

Filters

There are different types of filters: cellulose, polyester, polypropylene, acrylic, fiberglass, PTFE, Nanofiber, Aramids, Nomex, among others.

Diaphragm valves

These are normally placed outside the collector and are connected by a system of pipes to the equipment, which is actuated by a solenoid valve by means of a sequencer and thus shakes the filters, dislodging the dust accumulated in the filter.

Selenoid Valves

These valves allow the diaphragm valves to be actuated. In addition, these can be mounted in various ways either directly to the diaphragm valve or in a separate box.

Sequencer

This device is responsible for sending the electrical signal to the solenoid valves to activate the diaphragm valves and thus complete the filter cleaning cycle. The configuration of the sequencers varies according to the needs of each team. It can be continuous or based on need.

Colector de Polvos Industrial

Hoppers

It serves as a transition for the dusts collected from the application and when the cleaning system is active towards the discharge system.

Download System

Device to emit the discharge from the dust collector to a container outside the equipment, it can be a rotary valve, a drum lid, gravity or double weight valves, among others.

Design of a Dust Collector

The design of an industrial dust collector system must be carried out by specialists, who must gather all the necessary information for its manufacture and implementation. Some of the characteristics of dust collectors are that they can be designed and manufactured with a single unit or a collection of devices used to separate the particles from the process air.

It should be noted that although the production processes are similar in the companies, the calculations and operation are different, but each equipment is designed in a particular way.

Recommendations

- Before implementing an industrial dust collector to control dust, fumes or mists in the company, the type of material to be collected, the volume of air to be moved, must be considered, whether it is environmental extraction or localized extraction, among others.

- You should always consult with specialists, who should collect the necessary data to be able to carry out the design and for the correct implementation of it.

- Other factors to consider is the type of maintenance, performance and energy consumption, monitoring.

Colector de Polvos Industrial

Colector de Polvos Industrial

Colector de Polvos Industrial

Other articles of interest

Maintenance of a Dust Collector

In many companies, allocating resources to maintain their equipment is not a priority, because they consider that as long as they do not fail, they do not require attention or they simply see it as unnecessary. But, when these are damaged and need to be repaired, they realize the mistake that is made by not considering a preventive maintenance program and allocating resources to them.

Pressure Drops in a Dust Collector

In a Dust Collector, the differential pressure can be defined as the difference in pressure that exists between the dirty side of the filter chamber and the clean side of it, that is, it is the resistance that is generated when the air flow enters to the baghouse in the collector.

Air quality and its impact on Health and the Environment

For companies worldwide, one of the main concerns today is the impact of their production on the environment, air quality is a priority issue due to the risk it represents for…