filtro tipo bolsa, filtros para colectores, mantenimiento colectores, reparación de colectores, colectores industriales, colector de polvo, ventilación industrial, ventilación en empresas,filtro bolsa

mantenimiento colector de polvo, mantenimiento colectores, colectores industriales,mantenimiento de colector, filtro bolsa

How to select a bag type filter?

The performance of the bags or sleeves depends closely on the materials with which it is manufactured, as well as other factors. Choosing the right filter for a Dust collector It is very important, since the efficiency of capturing the particles depends on this and that the equipment has optimal performance during its operation.

The bags or sleeves must be designed and manufactured to measure for each particular situation, since the conditions vary from one scenario to another, the analysis of materials, air volumes, particle size, environmental conditions, etc; will affect the performance and life time of the bags. The reliability of the bags is very important, since the care of the bag also depends on Employee health and control of emissions into the atmosphere.

Therefore, you must ask yourself, what kind of properties does the powder have? What are the environmental conditions in which you are working? What other factors come into play in order to control dust?

Properties

The properties or characteristics of the dust will allow determining the type of filter media to use to achieve maximum performance, reduce wear, lengthen the life of the equipment and the filter.

Temperature and Humidity

Temperature and humidity are other factors to consider, for example, if you work with oils or aerosols in your manufacturing process, you must bear in mind that these have a moisture content of more than 20% and therefore the bags would not be a option for the collection of this type of wet powders.

In the case of temperature, you must know the parameters that you manage in your production processes, for example, if you have a temperature below 135 ˚C (275˚F) a bag made of polyester would be ideal, but if you manage a range above between 136 ˚C (277 ˚F) and 204 ˚C (277 ˚F) a bag with aramid material would be the best choice.

In other words, you must know perfectly what type of materials you want to control and the conditions in which they are worked in order to determine what type of bag would be your best option.

Chemicals

Also, if you work with chemicals, fuels or products that tend to be sources of ignition, it is very important to consider manufacturing the bags with special materials or having extraordinary measures in the Dust Collectors to protect the equipment in case of accidents.

DYNA FLO® Tips:

- Change all filters at each maintenance, do not change them for parts.

- Do not try to clean the filters manually, as you can damage them.

- Buy one maintenance policy for your Dust Collectors with us, avoid unnecessary delays.

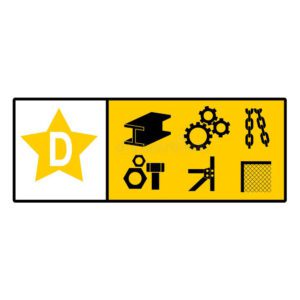

Collector Types

filtro tipo bolsa, filtros para colectores, mantenimiento colectores, reparación de colectores, colectores industriales, colector de polvo, ventilación industrial, ventilación en empresas

filtro tipo bolsa, filtros para colectores, mantenimiento colectores, reparación de colectores, colectores industriales, colector de polvo, ventilación industrial, ventilación en empresas, filtro bolsa

Other articles of interest

Is it important to measure air speed?

Before carrying out a project for the control of dust, fumes, mists or gases in the company, you must collect as much information and data that will allow you to carry out the correct and necessary calculations, one of the most important is that of the Speed of the Air or CFM.

Definition of air flow

It is the movement of air between two points, as a result of a pressure difference between them, with the direction of flow always being from the point of higher to lower pressure...

Rule 484 – Combustible Metals

Good practices in the management of Combustible Metals within companies are based on the NFPA (National Fire Protection Association) standard 484, this standard establishes the appropriate parameters for the prevention and management of these residues, such as: potassium , magnesium, zirconium, titanium, sodium and lithium.