Velocidad del aire, Sistemas de ventilación

Velocidad del aire, Sistemas de ventilación

Is it important to measure air speed?

Before carrying out a project to control dust, fumes, mists or gases in the company, you must collect as much information and data that will allow you to carry out the correct and necessary calculations, one of the most important is that of the Air Velocity or CFM.

What is air velocity?

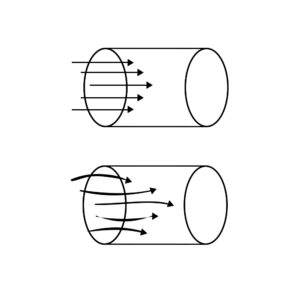

The airspeed, is generally defined as the movement that occurs in a horizontal direction to the Earth, this is not a mass of gas at rest, on the contrary, it is a very thin veil with fluidity and completely variable, with various thermal contrasts, this massive displacement of large masses of volumes of air with defined speeds and direction is called wind.

The airspeed, is one of the main data that we take into account for the design and manufacture of a dust collection system. Defining the capture speed will allow us to know the air flow, the diameter of the ducts, the collection area, the fan capacity, among other factors that will help maintain the speed of the air mass.

What is the air mass?

This is the most important consideration for the application in drying, combustion and general ventilation processes, which need a certain amount of air mass, these are usually measured in lbm/𝑓𝑡 ³ or Kg m/m³.

What is CFM?

The volumetric flow rate, hereafter called “volume“ (𝑣), is defined as the amount of air that passes a given place per unit of time. It is related to the average velocity and cross-sectional area of the duct given by the equation:

𝑄=𝑉𝐴

where:

Q = volumetric flow rate, cfm

V = mean velocity, fpm

A = área de la sección transversal, (〖𝑓𝑡〗^2 )

For instance; The capacity tables of industrial fan manufacturers are published in ACFM (Actual Cubic Feet Per Minute), the required air mass must be converted from SCFM (Standard Cubic Feet Per Minute) to ACFM (Actual Cubic Feet Per Minute). The transport speed in the system can be defined once we define the ACFM air volume.

The design of a dust collection system, fumes or ventilation system, part of the work of analyzing and calculating in real terms the volume or velocity of the air that must move and; thus being able to size and select the necessary components of the system to carry out the work, such as ducts, hoods, fan, etc.

DYNA FLO® Tips:

- Before investing in an industrial ventilation system, consult an expert in the field, give us a call.

Collector Types

Velocidad del aire, sistemas de ventilación

Velocidad del aire

Other articles of interest

Definition of air flow

It is the movement of air between two points, as a result of a pressure difference between them, with the direction of flow always being from the point of higher to lower pressure...

Renew my old dust collector?

If you are thinking of replacing your old industrial dust collector, but do not have the necessary budget, then you should consider revitalizing it. The integral maintenance of the equipment could revitalize it…

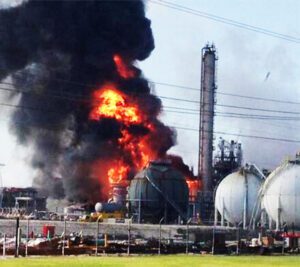

Explosive Atmosphere and Ventilation Systems

During the various production processes, there are some materials that can create an explosive atmosphere and therefore high risk if proper handling and control of them is not carried out, since these…