BLOG

Explosive Atmosphere and Ventilation Systems

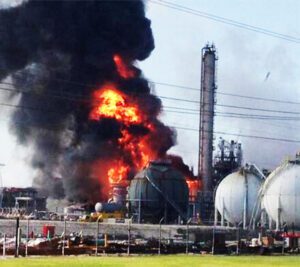

During the various production processes, there are some materials that can create an explosive atmosphere and therefore of high risk if proper handling and control of them is not carried out, since they release particles during the manufacturing processes, handling or storage,

To this can be added that the slightest spark, increase in temperature, oxidation or mixing of materials can cause ignition and generate an explosion with fatal results and considerable losses for the company. This is due to the fact that some particles suspended in the air, be they dust, fumes, mists or gases, can accumulate inside the buildings, warehouses or ventilation ducts and by not having an anti-explosion system in the ventilation systems and / or collection can lead to a loss.

Industrial Dust, Fume and Mist Collector systems DYNA FLO®, son equipos diseñados por nuestros ingenieros, los cuales son especialistas en el diseño de sistemas para la colección de polvos y sistemas de ventilación, esto permite que los equipos se puedan fabricar con características especiales para ayudar a resolver la problemática en la empresa, ya sea de giro industrial o comercial.

At Grupo Oasis contamos con personal especializado para brindarte la mejor solución y resolver tus problemas de control de polvos y ventilación industrial de forma eficiente.

Factors influencing an explosive atmosphere

An explosive atmosphere is generated when a flammable substance in the state of gas or vapor is mixed with air, in addition to ignition, combustion can spread to any substance that has not yet been affected. Thus, the explosive atmosphere can be generated by dispersion in air of flammable gases, vapors or mists.

For this reason, it is very important to know in detail the type of material with which to work, the conditions and the minimum security measures with which it must be operated, it is also essential in case of working with this type of mixtures, to know the limit Lower Flammability Limit (LII), Upper Flammability Limit (LSI), Lower Explosive Limit (LEL) and Upper Explosive Limit (LSE).

Security and Control

In order for a certain mixture of flammable gases or vapors in air to not produce an explosive atmosphere, it will be necessary to maintain a concentration control that is kept below the Lower Explosive Limit or above the Upper Explosive Limit.

Safe operation outside the flammability range can be achieved in air processes, however, processes that run below the lower flammability limit are safer. In general, whenever possible, the first option is chosen, through the implementation of suitable ventilation or extraction systems, for example, with the use of industrial dust, smoke or mist collectors, pumps or compressors, drying tunnels , kills sparks, to name a few.

Mata Chispa Cartridge Dust Collection System

Tips DYNA FLO®:

- Avoid the emergence of explosive atmospheres, consult with experts.

- Prevent fire in explosive atmospheres with specialized ventilation systems.

- Reduce possible damage to the health and safety of your employees, applying flammable substances handling protocols.

- Avoid possible damage to the company's infrastructure, with periodic reviews and constant monitoring.

- If you need a control system for dusts, fumes, mists and gases, call us!

Other articles of interest

What is an Electrostatic filter?

This type of filter allows the capture of micro particles such as cigarette smoke, soot, aerosols or bacteria that float in the environment, designed to help improve environmental conditions in hospitals, shopping centers, offices, movie theaters, to name a few. allow you to create a safe and comfort zone.

What are rotary or rotary valves?

A rotary valve or rotary valve is an equipment that allows to dose powder materials, this can be used regularly in silos, in hoppers, in endless bands, mixers, helical transport, dust collectors, among others.

How to select a bag type filter?

The performance of the bags or sleeves depends closely on the materials with which it is manufactured, as well as other factors. Choosing the right filter for a Dust Collector is very important, since the efficiency of capturing the particles depends on this and that the equipment has optimal performance during its operation.