Filtros Colector de Polvos duración

Ventiladores Axiales

BLOG

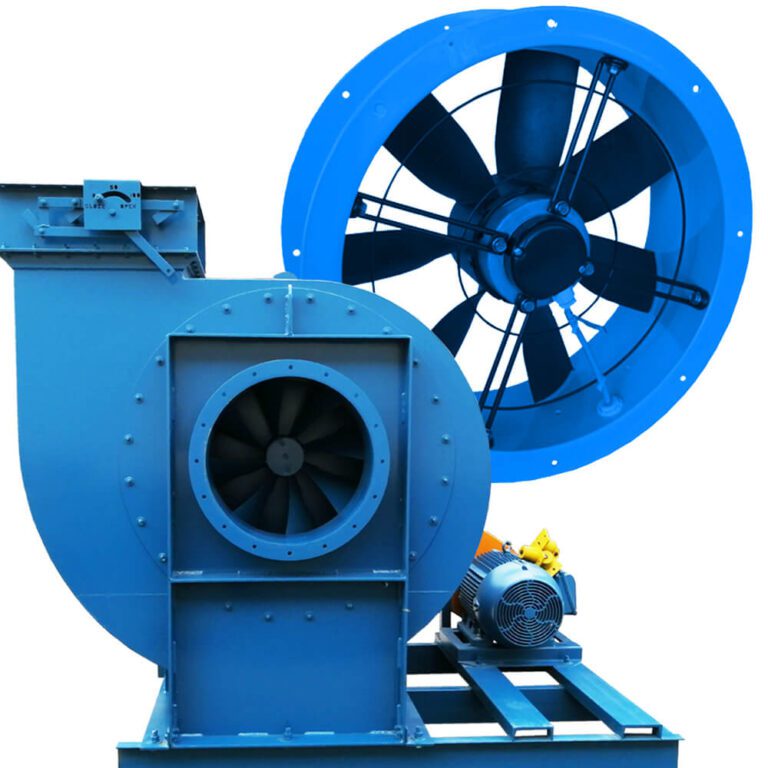

Axial or Centrifugal Fans

In order to move large volumes of air through a ventilation system or localized extraction system, in the vast majority of cases it is necessary to apply a lot of energy and this regularly comes from the fans, although in some cases it can also be applied naturally.

What are fans?

These machines are the most widely used in the entire industry to move air. Its function is to provide mechanical energy thanks to a motor that moves an arrow that in turn moves a rotor at high speeds, this allows to increase the kinetic energy of the fluid, to later transform into static pressure.

There are two great options of industrial fans: axial and centrifugal

Axial Type

In these fans, the flow of movement is through the rotor, with blades or blades placed in different ways, but keeping the direction towards the central axis of this.

Ideal for moving large volumes of air in open or clear spaces, their flow resistance is very low, the amount of static pressure to generate is very small, it is between 5 and 25 millimeters of water column (mmcda).

These equipment are regularly used in general applications, but if necessary, they can be designed and manufactured with blades with wing profiles and variable pitch, thanks to this, they can generate large static pressures close to 300 mmcda.

Centrifugal Type

This type of fan allows the air to enter in a direction parallel to the axis of its rotor, through the suction mouth and its discharge is carried out tangentially to it, that is, the air changes direction 90 °.

These equipments can develop much higher pressures than axial fans, reaching pressures of up to 1500 millimeters of water columns (mmcda); and they are commonly used in localized extraction systems.

Its operation is similar to that of centrifugal pumps, it is formed by a rotor that has vanes or blades, placed in a different way and curved, these rotate approximately between 200 and 5000 rpm inside a drawer.

Any type of fan must be designed, based on the collection of specific data, which must be manufactured in detail to provide an efficient solution, optimal performance, energy savings and low maintenance costs. Always seek advice from expert personnel on the subject.

Call us, we are ready to help you solve the ventilation needs of your company.

DYNA FLO® Tips:

- Before investing in an industrial fan for your ventilation system, consult an expert in the field.

- The fans may look the same for all cases, but their application and capacity vary, be sure to invest in the right one.

- If your production increases, then your environmental pollutants too, this can impact the performance of the fans.

Collector Types

Ventiladores Axiales Centrífugos

Filtros Colector de Polvos duración

filtros

Other articles of interest

What is the function of an Industrial Dust Collector

La industria en todo el mundo genera a diario grandes volúmenes de contaminantes, esto debido a los diversos procesos de producción, lo que afecta directamente a la calidad del aire dentro de las fábricas…

How long do the filters in an industrial dust collector last?

The lifetime of new filters, whether they are bag or cartridge type, can be determined during the first days of operation. Any type of filter, with the exception of those with a Teflon membrane, uses the layer of dust that accumulates on the surface of these to clean dirty air.

Combustible Dusts

Combustible dusts are considered all those materials that have as part of their properties the ability to catch fire or generate an explosion. The NFPA 654 of the year 2006 defines it as any solid particle that represents fire or deflagration, regardless of its size.