can velocity colector de polvos, filtro para colector, filtraciones, colector, filtros industriales, flujo de aire

can velocity colector de polvos

What is CAN Velocity?

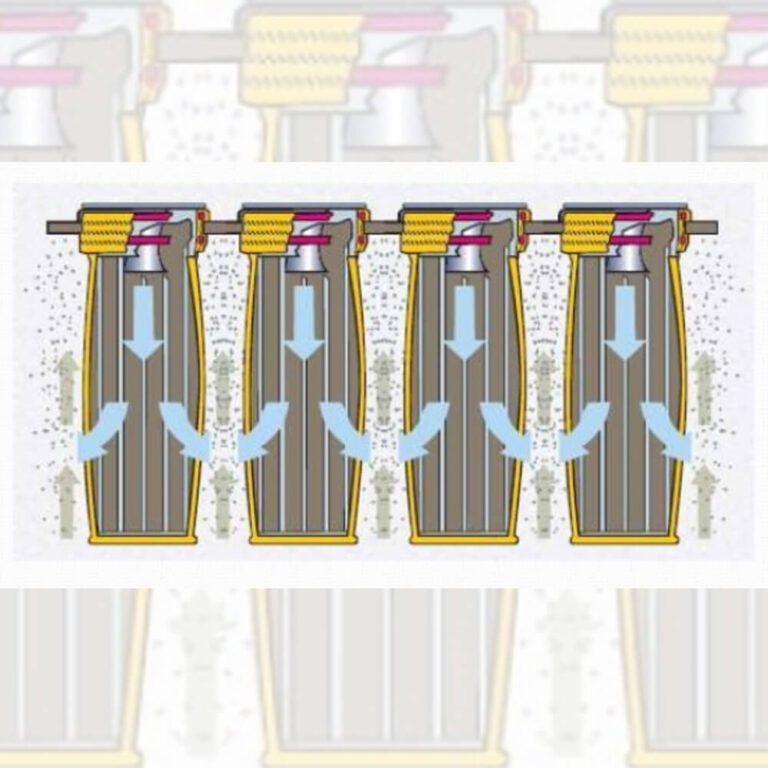

Interstitial Velocity, or CAN Velocity, is defined as the upward velocity of air through the open area between filter bags within a dust collector.

Consider this in the design of your Dust Collector

When sizing a Pulse-Jet Dust Collector, it is very important to consider the relationship between filter media and pore velocity or CAN Velocity. The upward speed occurs when the air leaks through the lower part or the hopper area and rises towards the baghouse, that is, from the bottom up, which causes it not to be captured at all.

In order to determine the CAN Velocity, it is calculated in ft / min and determined by dividing the volume of dirty air entering the collector chamber (body) by the net area of flow available in the direction of flow.

The net flow area is determined by subtracting the total axial sectional area of all filters from the total cross sectional area of the collector body.

Other considerations

A Dust Collector can be economical in its initial investment, this can be achieved if you want to reduce the size of the body, but consequently the CAN Velocity will be increased, which is important to take into account, since the correct operation and material download.

Another factor to consider is the short-time replacement of the filter media, because saturation due to high filtration speeds will saturate the filters faster, shortening their life time. This could consequently increase the cost of each filter replacement. A possible solution to reduce costs is to use surface filtration to tolerate high filtration speeds, which would allow the use of less filter media, thus reducing the CAN Velocity.

If the CAN Velocity is very high, the dust that is detached from the filter during the cleaning pulses and is dragged back to the top of the baghouse, can be recaptured along with the dirty air streams entering the collector. .

Indicators with high CAN Velocity values can be very similar to those obtained by high filtration speeds, but the solution is different. Instead of the filters becoming saturated, the dust accumulates only on the surface of the filters, since it cannot be expelled or taken out of the chamber, this will cause an increase in the differential pressure, but changing the type of filter media, you can be of no help, unless the new filter media is capable of handling the high filtration rates.

If you need a Dust Collector, contact us and we will gladly help you solve your dust, smoke or mist control problems.

DYNA FLO® Tips:

- The calculations to know the CAN Velocity must be carried out by specialists and verify that they are correct.

- Always consult with us about any situation in your dust collectors.

- Our engineering department has highly specialized staff ready to provide you with the best service to solve the needs of your company in matters of dust, fume or mist control.

Collector Types

can velocity colector de polvos, filtro para colector, filtraciones, colector, filtros industriales, flujo de aire

can velocity colector de polvos, filtro para colector, filtraciones, colector, filtros industriales, flujo de aire

Other articles of interest

Frequently Asked Questions about Dust Collectors

La industria para poder controlar polvos, humos, neblinas o gases, deben contar con sistemas especializados o deben invertir en ellos, estos sistemas obligan a plantearse diversas interrogantes, ya que…

Renew my old dust collector?

If you are thinking of replacing your old industrial dust collector, but do not have the necessary budget, then you should consider revitalizing it. The integral maintenance of the equipment could revitalize it…

Benefits of Preventive Maintenance

Have you ever wondered how much money preventive maintenance on your equipment or machinery saves you? It is undoubtedly one of the most frequent questions we ask ourselves while making budgets for this area in companies.