Tipos de Colectores industriales

BLOG

Types of Industrial Collectors

Systems industrial collectors, have their beginnings around 1886, their inventor was the engineer Wilhelm Friedrich Ludwig Beth, who was a mill builder like his father, Wilhelm Ludwig, seeing the need for a system that would allow controlling the powders that were generated during the grain mills of that time ...

had an idea, decided to design and create a suction system, which allowed dust to be sucked through filter media, by 1887 he managed to found his own company WFL Beth Maschinenfabrik, which would become the pioneer of a large industry for the dust control in the world.

During later years Wilhelm, would design new models for dust control, which it would begin to implement in hard grinding, such as the crushing of rocks, minerals, marble, ores and cement production, these equipment were quickly recognized by the Health sector of the time, highlighting that these filtering systems greatly improved the air in the work areas, later in 1921 he managed to patent three types of filters to eliminate dust, thereby achieving a position as a necessary equipment for dust control and employee health care .

Types of Collectors

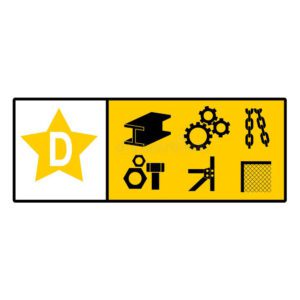

At present, there are a great variety of industrial collectors for the control of dust, fumes and mists, some of the most common types are:

These industrial collection systems can also be classified as: inertia or gravity, air washing, electrostatic or mechanical, in addition, these can be used directly in production lines, whether they are industrial or commercial business anywhere in the world.

Tipos de colectores industriales

Use of Industrial Collectors

These are some of the applications that dust, smoke or mist control systems can have; for example:

Applications

- Synthetic plaster

- Products

- Felt cloth

- Textile companies

- Glass

- Gold foundry

- Silver foundry

- Bronze foundry

- Inert carbon

- Lead oxide

- Molybdenum

- Smoke from Welding

Applications

- Oily

- Spice powder

- Grinding machines

- Wood dust

- Furniture factory

- Aluminum Powder

- Cement

- Plastic Powder

- Fiberglass

- Fumes foundry

- Brush Manufacturing

- Litter bins

- Rice powder

Applications

- Plastic factory

- Recyclers

- Rubber factory

- Clays

- Grinding Powder

- Iron foundry

- Sanding and Detailing

- HDPE Plastic Powder

- Laser Cutter Powder

- Sandblasted

- Sugar bowls

- ZINC Galvanized Factories

Applications

- Silica

- Pharmaceutical Powders

- Robotic Welding Fumes and Fumes

- Welding fumes

- Pedreras

- Marble shops

- Ceramics

- Mining

- Chrome Powder

- Oil Mists

- Oil fumes

- Refrigeration Mists

- Others

Smart Collectors

The constant expansion of the industry and the growth of production in the world, is having a positive impact on the economy, but negative on the environment; Mexico is no stranger to this situation, nowadays most Mexican companies focused on the industrial or commercial sector are investing in production technologies, such as industrial dust collector systems, which must be designed by specialists and specifically To solve the control needs of dust, fumes, mists or gas, these equipment must also have the highest quality standards and digital technology that allows its operation, performance, as well as, to be monitored at all times and from anywhere. program self-cleaning cycles (pulse jet), reduce energy consumption, among other functions that make them smart systems.

Industrial Dust, Fume and Mist Collector systems DYNA FLO®They have all the necessary technology and adhere to the highest quality standards worldwide. Having intelligent equipment that provides information in real time, allows companies to save on costs and those in charge of their operation to schedule maintenance, carry out filter changes on time and, most importantly, reduce the impact of their production on the environment. as well as taking care of the health of the employees within its facilities.

Recommendations

Before implementing an industrial collector to control dust, fumes or mists in the company, the type of material to be collected, the volume of air to be moved, must be considered, whether it is environmental extraction or localized extraction, among others. You should always consult with specialists, who should collect the necessary data to be able to carry out the design and for the correct implementation of it.

Other factors to consider is the type of maintenance, performance and energy consumption, monitoring.

Other articles of interest

What are rotary or rotary valves?

A rotary valve or rotary valve is an equipment that allows to dose powder materials, this can be used regularly in silos, in hoppers, in endless bands, mixers, helical transport, dust collectors, among others.

Rule 484 – Combustible Metals

Good practices in the management of Combustible Metals within companies are based on the NFPA (National Fire Protection Association) standard 484, this standard establishes the appropriate parameters for the prevention and management of these residues, such as: potassium , magnesium, zirconium, titanium, sodium and lithium.

How long do the filters in an industrial dust collector last?

The lifetime of new filters, whether they are bag or cartridge type, can be determined during the first days of operation. Any type of filter, with the exception of those with a Teflon membrane, uses the layer of dust that accumulates on the surface of these to clean dirty air.