errores colector de polvos, colector

errores colector de polvos, colector

Common mistakes when investing in a Dust Collector

As head of the maintenance, purchasing or manager area, one of the main responsibilities when requesting the purchase of equipment to solve a problem in the company is to have all the necessary information to be able to evaluate and make the best decisions. The search, selection of the supplier and purchase of the equipment depends on the needs that need to be solved.

Investing in a Dust Collector is a very important issue for any company, regularly the dust collection systems are perceived negatively by investors, this is because they have probably heard bad references about these in other companies and / or that do not generate performance and / or value. But the reality is that Dust Collectors allow companies to improve indoor working conditions, cleaning the air of pollutants that can cause illness in their employees, air filtering can also be reused to inject clean air indoors. of the workplaces, allow compliance with environmental protection standards and are equipment with great energy savings.

Here are some common mistakes when investing in a Dust, Fume or Mist Collector:

Human factor

The lack of information on the needs to be solved, are usually the root of the problems and difficulties before buying a Dust Collector. The human factor, in most cases, predisposes that investment in a collection system is not necessary for the company or that it will not solve the problem since they do not know how it works.

That is why, before buying a dust collector, it is necessary to carry out a survey of the needs by personnel with knowledge in ventilation and dust control systems.

The wrong provider

In the vast majority of cases, dust collectors are viewed as an unnecessary purchase and are therefore taken lightly by stakeholders. Selecting the supplier without knowing its reputation, projects carried out, capacity, etc., causes that at the time of assigning and carrying out the projects they do not provide the solution that is required and therefore generate the perception that buying a collector is a wrong investment .

Before assigning a project as important as a Dust Collector System, consult and compare.

Air Volume Deficiencies

Another common mistake when investing in a Dust Collector is not making the necessary calculations, among them the most important is the volume of air to handle; In addition, the various factors that may intervene in it and affect the operation of the system must be taken into account.

By having the correct calculations of the air volume, we can make assertive decisions for its manufacture, for example, if the company is growing and they recommend a team that handles the right air volume, this could cause that later on you have to reinvest into a new team or readjust the one they have. For this reason, it is very important to know all aspects of the company, its operation, growth plans, production, etc., with this information you can choose the best equipment for controlling dust, fumes or mists and their components, it is always better to stay always a little left over in the capacity of the dust collector.

Noise emission

Noise is another factor to consider when investing in a Dust Collector, the management of the noise decibels inside or outside the plant should be considered at the time of manufacture, the noise is normally caused by the fan the which, due to its function, tends to generate it, but it is the supplier's responsibility to verify that this equipment does not exceed the permitted levels, and the noise it generates can be attenuated with the installation of acoustic booths or silencers.

Deficiencies in ductwork design

Another important element that makes up a Dust Collector system is the ductwork and this is regularly disregarded during design. A bad calculation in the ductwork network can generate a deficiency between 50% and 60% of what should be collected during the operation.

Any alteration to the ductwork, for example, that the company makes any modification or moves the ductwork from place or path will generate inefficiency in the collection system, this should be consulted with the supplier to verify the effects on the catchment capacity, since it would also result in a modification in the minimum speed and material settlements would occur. The expert must make the necessary adjustments for the correct operation of this.

Before carrying out any modification or maintenance to your collector, consult us, we are here to help you.

Filtration deficiency

Filtration capacity is the total volume to be handled divided by the filtering area of the collector.

For each type of dust, there is a filtering ratio and this can also be calculated with all the information obtained and according to the application to be more exact in recommending what type of filters should be used, capture speed, type of hood. , etc.

In most cases, a miscalculation of the filtration capacity causes deficiencies in the capture of dust, generating poor collector performance and premature clogging of filters.

Rotary malfunction

Commonly, dust collection systems work by suction, that is, the fan is on the clean side, when this is the case, the rotary blades must be checked, that they are performing their function correctly, that the seals and gaskets are in place. in good condition, this because, if the seals are not good, this can cause false air inlets, allowing air currents to cause the collected product to rise inside the dust collector, causing in turn an increase in differential pressure, affecting the suction capacity of the hoods.

Not considering a budget for maintenance and spare parts

One of the most common mistakes in companies when investing in a Dust Collector is that they do not consider maintenance, replacement of parts and filters, energy consumption, to mention the most common and that in the long run will generate an expense.

Failure to consider an adequate budget for the maintenance or replacement of parts and filters, as well as extraordinary events, can affect the economy of the company.

For this reason, the supplier of all fixed or extraordinary expenses should be questioned in order to have them present in the budgets.

DYNA FLO® Tips:

- Before investing in an industrial ventilation system, consult with us, call us and we will gladly assist you.

Collector Types

errores colector de polvos, colector

errores colector de polvos, colector

Other articles of interest

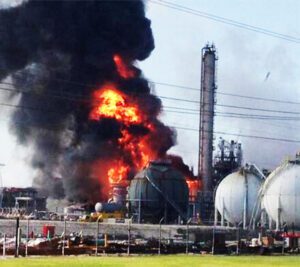

Explosive Atmosphere and Ventilation Systems

During the various production processes, there are some materials that can create an explosive atmosphere and therefore high risk if proper handling and control of them is not carried out, since these…

Is it important to measure air speed?

Before carrying out a project for the control of dust, fumes, mists or gases in the company, you must collect as much information and data that will allow you to carry out the correct and necessary calculations, one of the most important is that of the Speed of the Air or CFM.

Filtration speed

It can be defined as the proportion of air that passes through the filter cloth, that is, the amount of air that passes through each square foot of the filter media area per minute.