mantenimiento colector de polvo, mantenimiento colectores, colectores industriales, polvos combustibles, colectores industriales, colectores para industrias, filtrado de neblinas, filtrado de humos, neblinas, niebla, empresas de ventilación industrial

mantenimiento colector de polvo, mantenimiento colectores, colectores industriales, polvos combustibles, colectores industriales, colectores para industrias, filtrado de neblinas, filtrado de humos, neblinas, niebla, empresas de ventilación industrial

Workstations and the right collector

Industries dedicated to manufacturing or assembly, in their distribution within the plant, implement small, compact and versatile areas, called work stations. These are regularly placed in series, since this makes the production lines more efficient.

The distribution or location of these depends to a large extent on the type of activity to be carried out, materials with which they are going to work, chemical products to be used, etc; that is why a work station must be versatile and provide safety to workers.

An ergonomic work station can increase productivity, improve safety, guarantee the quality of work and contribute to the health care of the worker. The worker's activities will determine the space, equipment, etc.; Since this largely depends on its integrity, it is very important to take into account whether the employee will be in direct or indirect contact with toxic materials, such as dust, gases, acids, solvents, to name a few.

1. Analyze how many workstations you require.

Carrying out a prior analysis will allow you to determine the average number of workstations that you require, this will help not to place stations that are not used and have a higher cost for the company.

Prepare a feasibility study focused on your production chain, rely on your engineering department.

2. Improve productivity

In your company there may be production processes, in which their specialization, precision and detail require to be automated.

You can make your workstations more productive by automating their process.

3. Technology and peripheral equipment

Workstations must be accompanied by technology that allows workers to carry out their activities more efficiently, in less time, however it is very important not to saturate the space, as this can be counterproductive.

In the case of automated stations, the software is essential for its operation, electricity, tools, etc.

4. Ventilation System

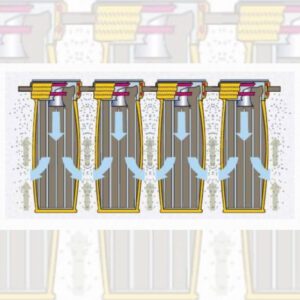

Ventilation in work stations where welding, detailing or polishing processes are carried out, to name a few, is important; have a team that helps control dust or fumes emanating from these processes.

An industrial collector with localized extraction is sometimes the best solution, but sometimes, depending on the size of the workstations, an environmental or general collector could be the solution.

DYNA FLO® Dust Collectors meet all the characteristics of flexibility and adaptability to solve problems with dust and fume control.

5. Includes storage and circulation areas

Contemplating storage spaces at key points will save time and reduce the periods of transfer of materials or supplies.

A waiting area would be ideal with optimal visibility in case the workstations are not automated, so workers can see if they have materials available or request more in advance.

In short, make sure that your workstation has the necessary elements that provide flexibility and ergonomics, but without it being saturated with unnecessary things, employee safety must be a priority, ventilation plays a very important role. important.

DYNA FLO® Tips:

- Hire an expert to identify potential risks in your company.

- A DYNA FLO dust collector is always a good option to help control and reduce dust risks.

- If you require a reliable analysis to implement the best solution for dust control, contact us, we are ready to help you.

Collector Types

dust collector maintenance, collector maintenance, collectors

polvos combustibles, colectores industriales, colectores para industrias, filtrado de neblinas, filtrado de humos, neblinas, niebla, empresas de ventilación industrial

Other articles of interest

CAN VELOCITY

Interstitial Velocity, or CAN Velocity, is defined as the upward velocity of air through the open area between filter bags within a dust collector.

Benefits of Preventive Maintenance

Have you ever wondered how much money preventive maintenance on your equipment or machinery saves you? It is undoubtedly one of the most frequent questions we ask ourselves while making budgets for this area in companies.

Discharge Systems

In dust control systems, one of the essential parts that are not important to investors are the discharge systems. This is often due to the fact that the important function it has is unknown, in addition to being the lower part and the least striking it is less relevant.