velocidad de filtración en colector, filtros colectores

velocidad de filtración en colector, filtros colectores

Filtration speed

It can be defined as the proportion of air that passes through the filter cloth, that is, the amount of air that passes through each square foot of the filter media area per minute. This can be calculated by dividing the Air Flow Amount (CFM) by the number of square feet of total filter in the dust collector.

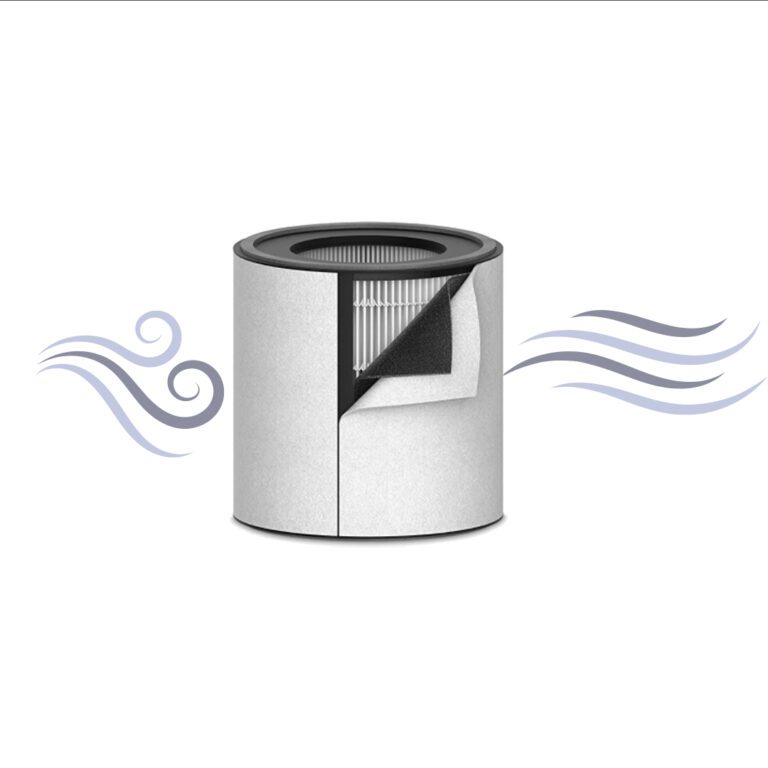

Filter media

The area of the filter media is the total amount of filter media in the dust collector, usually measured in square feet. The higher the CFM and the more particulate you are generating, the more air filtration cloth media you will need.

Some other terms used to refer to the filtration speed are: filtration ratio and fabric air ratio, but they all refer to the same thing, the amount of volume of air that will be passing through the total filter area.

This is a key point when buying a Dust Collector.

The filtering relationship and the application

In order for it to function correctly, the type of application for which it is to be used must be known, since each type of powder has its own filtering ratio and, even more, the necessary calculations must be carried out to determine its efficiency. .

A bad practice in the filtering ratio is the famous “rule of thumb”, which is not recommended at all. To determine the filtering ratio, the appropriate calculations must be carried out to support this factor. In this part, the human factor plays a very important role, the person in charge of the engineering area or the seller must ask the interested party all the details of the production and the waste generated in order to carry out the analysis and determine what type of application it is the ideal; the product, type of application, amount of material to collect, density, among others, are very important to take into account when selecting the filtration speed.

Failed to select filter ratio

The rapid saturation of the filters is one of the main problems that can arise when the filter ratio is not correctly selected, this will cause the suction in the hoods to be deficient and will promote the emission of dust, in addition to increasing the differential pressure by the saturation of the cartridges the speed in the ducts will decrease causing the settlement of residues in it.

Another problem that could arise when not selecting the correct filtering ratio is that the filters can break, this happens due to a greater load of air volume than initially estimated, in case a filter breaks, the expulsion of waste will be seen down the chimney into the atmosphere and problems will begin in the system.

In case of reaching this point, the fan will be affected, because it will be in direct contact with residues that alter its balance or damage it.

Filtering speed: Bag type or Cartridge type filter

Each filter has its own filtration capacity and speed.

The bag filters, they can handle a much higher filtration rate or filtration ratio than cartridge type filters. Manufacturers of bag-type filters guarantee an efficient filtration ratio of between 5: 1 & 10: 1 (as long as taking care of the important factors to consider) being that, for the filtro tipo cartucho, the filter ratio can range from 0.5: 1 to 3: 1 this depends mainly on the type of material and filter media selected.

DYNA FLO® Tips:

- Always replace all filters at each maintenance.

- Do not blow the filters, as you could break them.

- Before investing in an industrial ventilation system, consult an expert in the field, give us a call.

Collector Types

filtros colectores, velocidad de filtración en colector

velocidad de filtración en colector, filtros colectores

Other articles of interest

Colectores portátiles y la industria farmacéutica

En todo el mundo, la fabricación de medicamentos es un proceso que requiere de los más altos estándares de calidad, seguridad y eficiencia. Uno de los aspectos más importantes para garantizar estos requisitos es el control de la contaminación por polvos, que puede afectar negativamente a la salud de los trabajadores, al medio ambiente y a la integridad de los productos farmacéuticos.

Discharge Systems

In dust control systems, one of the essential parts that are not important to investors are the discharge systems. This is often due to the fact that the important function it has is unknown, in addition to being the lower part and the least striking it is less relevant.

The importance of a dust collector in a foundry.

Metal foundries play a very important role in the production of various products around the world, from aeronautical parts, automobiles, industrial components and for our daily lives. However, this industrial process can generate large amounts of dust and suspended particles that pose risks to both workers and the environment.