sistemas de descarga colector de polvos, colector de polvo, capacidad de descarga, válvula

sistemas de descarga colector de polvos, colector de polvo, capacidad de descarga, válvula

Discharge Systems

In dust control systems, one of the essential parts that are not important to investors are the discharge systems. This is often due to the fact that the important function it has is unknown, in addition to being the lower part and the least striking it is less relevant.

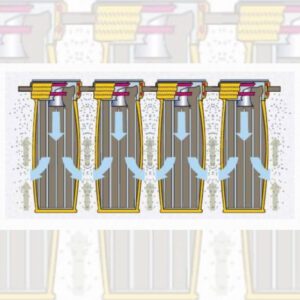

The implementation of a Dust Collector in a company is only the first step to control the particles and avoid their accumulation. For a dust collection or control system to function properly, it is necessary that the captured dust be dislodged or properly disposed of outside the collector and the business.

In order to dispose of the powders captured during the filtering process, it is necessary to have a good pneumatic seal after the hopper, which is a part of the collector, serves as a transition and allows to dispose of the residues that are collected by the suction hoods. .

What if you don't have a good pneumatic seal?

In the absence of a suitable seal, two things can happen:

- External air may enter from the bottom of the collector, causing a decrease in dust and suction control at the capture points

- If air leaks through the bottom of the collector, this will cause the dust to rise or return inside the collector and cannot be discharged, this will cause a higher differential pressure and will shorten the life of the filters.

The hoppers are only the first part of the discharge system in a collector, their function is not to store, but to serve as a transition part, the dust or residue passes through it and falls into a rotary valve to dose its disposal in bags. or tambos.

The wrong provider

In the vast majority of cases, dust collectors are viewed as an unnecessary purchase and are therefore taken lightly by stakeholders. Selecting the supplier without knowing its reputation, projects carried out, capacity, etc., causes that at the time of assigning and carrying out the projects they do not provide the solution that is required and therefore generate the perception that buying a collector is a wrong investment .

Before assigning a project as important as a Dust Collector System, consult and compare.

Rotary valves

This is a very important element in the dust collector, its function is to dose and complete the pneumatic seal for the correct operation of the system.

There are different types of arrangements and finishes for rotary valves, these are normally made of carbon steel, but they can also be made of stainless steel, for food grade and / or corrosion, this totally depends on the application in which it will be used.

DYNA FLO® rotary valves are high quality manufactured parts. Designed with high resistance and efficiency, we have a great variety and capacity.

Noise emission

Noise is another factor to consider when investing in a Dust Collector, the management of the noise decibels inside or outside the plant should be considered at the time of manufacture, the noise is normally caused by the fan the which, due to its function, tends to generate it, but it is the supplier's responsibility to verify that this equipment does not exceed the permitted levels, and the noise it generates can be attenuated with the installation of acoustic booths or silencers.

How to define the capacity of a rotary valve?

The first thing we must know to be able to correctly determine the type of valve that we require, is the application in which you want to implement, to know the type of material that will pass through it. The second thing we must know is the amount of material that it will handle, the volume that it will be passing per minute. You must know these data perfectly since with them you will determine the capacity, size and manufacturing material.

Calculate the capacity of the rotary valve can be obtained as follows:

CCP= CVxDMxRPM

Where

CCP: Capacity Calculation

CV: Volumetric Capacity

DM: Material Density

RPM: Revolutions per Minute

To obtain a correct calculation on the type of valve you require for your discharge system, you must approach us and we will gladly support you.

DYNA FLO® Tips:

- Before investing in an Industrial Dust Collector, consult with us, call us and we will gladly assist you.

Collector Types

sistemas de descarga colector de polvos, colector de polvo, capacidad de descarga, válvula

sistemas de descarga colector de polvos, colector de polvo, capacidad de descarga, válvula

Other articles of interest

How to improve the air flow of your Centrifugal Fan?

Los diversos procesos de producción industrial y los Sistemas de Ventilación en las Plantas, en algunas ocasiones requieren incrementar el flujo de aire para el que originalmente fueron calculados los equipos, por ejemplo…

Renew my old dust collector?

If you are thinking of replacing your old industrial dust collector, but do not have the necessary budget, then you should consider revitalizing it. The integral maintenance of the equipment could revitalize it…

CAN VELOCITY

Interstitial Velocity, or CAN Velocity, is defined as the upward velocity of air through the open area between filter bags within a dust collector.