válvulas rotativas rotatorias

válvulas rotativas rotatorias

BLOG

What are rotary or rotary valves?

A rotary valve or rotary valve is an equipment that allows to dose powder materials, this can be used regularly in silos, in hoppers, in endless bands, mixers, helical transport, dust collectors, among others.

It is regularly made of carbon steel or stainless steel like most of its components.

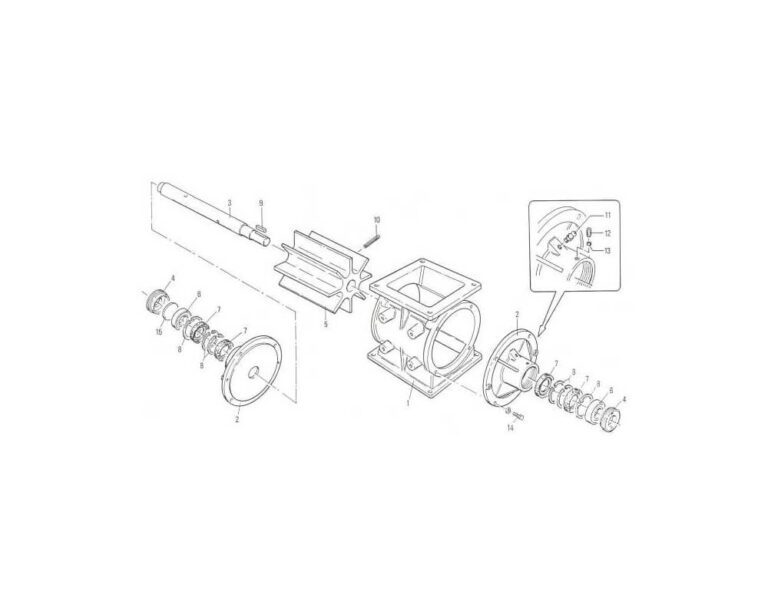

Elements of a rotary valve

The rotary valves are formed by a central body, regularly made of steel, which is very resistant, inside it a rotor is housed which is formed by fins, which transport the product from the top to the bottom, this in turn It is held by a steel shaft, two caps on both sides of the body that reinforce the body and allow easy access to the rotor for maintenance, and a central shaft which is also made of steel.

The valve is actuated by a geared motor, which is designed to supply great power and accept large radial loads.

What is your function?

The main function of a rotary valve is to allow the dosing of the powder residues or granulated material, which are generated during various industrial processes, an internal rotor acts as a dispenser, since depending on the space between its fins it allows the quantities of powders or residues are adequate to displace during a certain period of time. On the other hand, they also have the function to avoid false air inlets and allow a hermetic closure in the discharge of a dust collector.

These must be resistant to abrasion, high temperatures and high pressure.

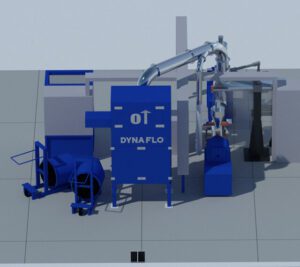

At Grupo Oasis, we develop your project from start to finish, we have specialized personnel to find the best solution for your company. Call us!

Rotary Valve Implementation

Rotary valves are used in the vast majority in the various industrial production processes around the world, regularly these intervene where you work with dusty products such as flour, sugar, cement, lime, clays, medical reagents, chemicals, plastic materials , shredded and many others.

In addition, there are other types of rotary valves that can be implemented in manufacturing processes where wood is involved, such as carpentry or furniture factories, these are specially designed and manufactured with a rotor with rubber blades, which are covered with fabric. In this process, we have equipment with a large opening in the buckets for proper unloading and avoiding material plugging.

Also, there are the rotary valves made of stainless steel, which are regularly implemented in industrial processes where a lot of hygiene is required, such as in the manufacture of medicines, chemical elaboration, food, as well as in any other process in which it is requires a high degree of cleanliness and safety. This type of rotary is manufactured with special materials that prevent residues from sticking to their parts or becoming contaminated.

If you need a rotary valve, call us with pleasure we will help you.

DYNA FLO® Tips:

- Periodically check the correct operation of your rotary valve.

- Replaces damaged parts with new and original ones.

- Consider maintenance in your budgets.

- Always take into account the opinion of the maintenance staff.

Collector Types

válvulas rotativas rotatorias

válvula

Other articles of interest

Workstations and the right collector

Industries dedicated to manufacturing or assembly, in their distribution within the plant, implement small, compact and versatile areas, called work stations. These are regularly placed in series, since this makes the production lines more efficient.

Benefits of a Mist Collector

In metallurgy and machining processes it is very common for mists to be generated, due to the nature of the various production methods. The detachment of micro particles that remain in the work environment…

What is the function of an Industrial Dust Collector

La industria en todo el mundo genera a diario grandes volúmenes de contaminantes, esto debido a los diversos procesos de producción, lo que afecta directamente a la calidad del aire dentro de las fábricas…