BLOG

Interpreting the pressure differential

If the pressure differential is less than expected, look between:

- Inappropriate system design that reduces the amount of air to levels below design.

- Air leaks at some point in the duct system Blockage at some point in the system. Fan operating in the opposite direction.

- Broken or misplaced filters.

More on the pressure differential.

If the pressure differential is less than expected, look between:

- Improper system design that increases the amount of air in the system above the design.

- Clogging inside the dust collector (filter media)

- Air leaks at some point in the system.

If the pressure differential is suddenly stable low, look between:

- Loose or broken fan belts.

- A broken or fallen filter.

- Plugging at some point in the duct system.

- Air leaks somewhere in the duct system.

At Grupo Oasis we have specialized personnel to provide you with guidance on your projects.

If the pressure differential is the filters being stable suddenly rises, look between:

- Collector cleaning system malfunction.

- Partial filter plugging that needs replacement.

- Air leaks somewhere in the duct system.

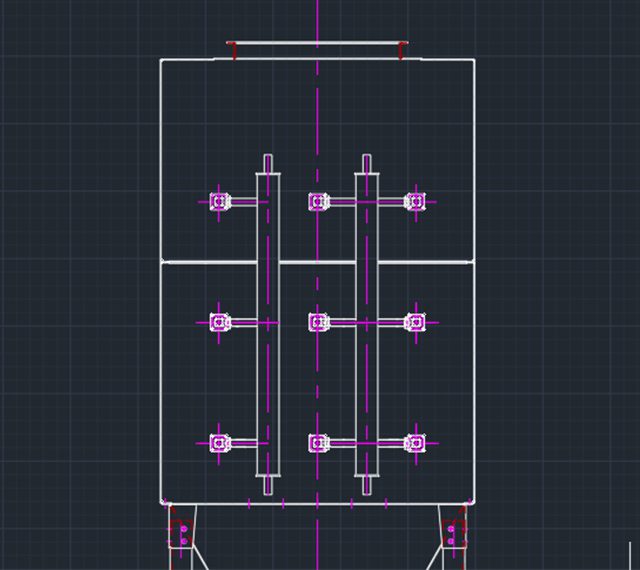

Filter cleaning system.

The filters in a dust collector must be cleaned periodically since the dust accumulates on the surface of the filters forming a “CAKE” that acts as the pre-filter of the same filter. Eventually this layer of dust increases the resistance of the air through the filters, sometimes dramatically decreasing the volume of air that is being handled in the system.

The cleaning system is automatic with bursts of compressed air that is supplied by diaphragm valves actuated sequentially by solenoids electrically commanded by a solid state TIMER. The quality of the compressed air must be taken care of and it must be supplied clean and dry and at a pressure of 90-100 Lbs / in².

Tips DYNA FLO®:

- It is very important to take into account the following, when changing filters during the maintenance of your dust, fume or mist collector, make sure to replace all of them, it is not recommended to carry out this activity partially, since they can cause a equipment malfunction.

- To clean the filters, it is not necessary to remove them, be sure to turn off the fan and let the compressed air cleaning system run for at least 15-20 minutes. If when the fan is turned on again, the pressure differential remains high, then it is time to change the entire batch of filters.

- It is not recommended to wash the filters, since by not doing the required permeability tests, many fine particles remain occluded between the interstices of the media, partially covering it.

Riesgo de fuego / Grupo OASIS fabricamos colectores de polvos humos y neblinas. La versatilidad de nuestros Colectores de Polvos, Humos y Neblinas marca DYNAFLO®. brand, the attention to detail during the manufacturing and installation process allowed us to work in Mexico and United States.Nuestros clientes de las industrias agroalimentaria, cementera, química, cerámica, automotriz, acerera, entre otras más nos respaldan.Nuestra amplia gama de productos como colectores de polvos, colectores de humos, colectores de neblinas, ciclones, colectores de humos portátiles, ventiladores industriales, válvulas rotatorias, filtros y refacciones, además de proyectos llave en mano, capacitación y mantenimiento de equipos nos permiten brindar servicios integrales. / Riesgo de fuego

Other articles of interest

Types of Industrial Collectors

Industrial collector systems have their beginnings around 1886, their inventor was the engineer Wilhelm Friedrich Ludwig Beth, who was a mill builder like his father, Wilhelm Ludwig...

Oil mists

The workshops that work with specialized equipment such as CNC or lathes, require the use of liquids such as water and oils, aerosols are also used in some of these machining processes, these must be controlled at the point where they are generated, preventing them from come into contact with workers.

Hoppers: Function and Application

The hoppers are part of the structure of the dust collectors, they fulfill a very important function, which is to channel the materials, whether they are granulated, pulverized, among others, towards the container where the collected material will be stored. These are mounted on a rigid chassis that serves as a support, their shape is regularly conical and with sloping walls.